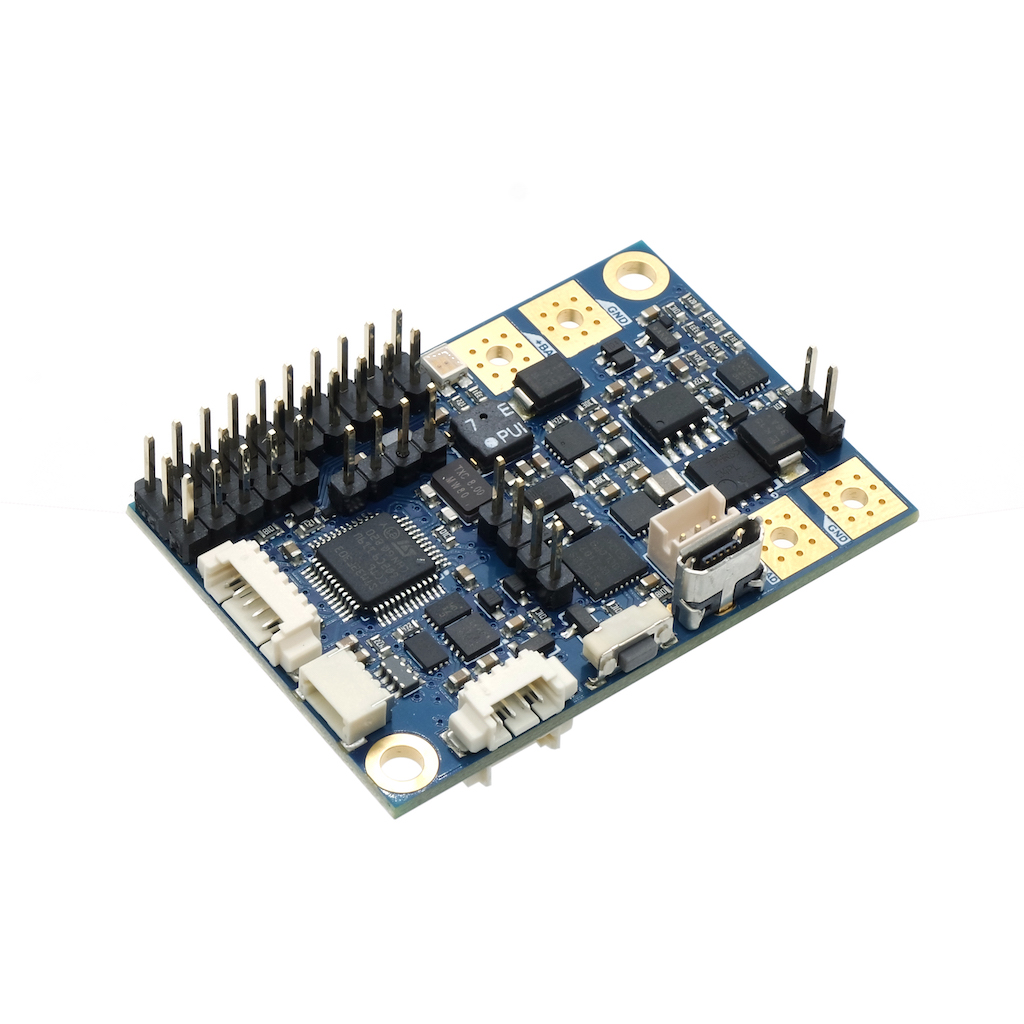

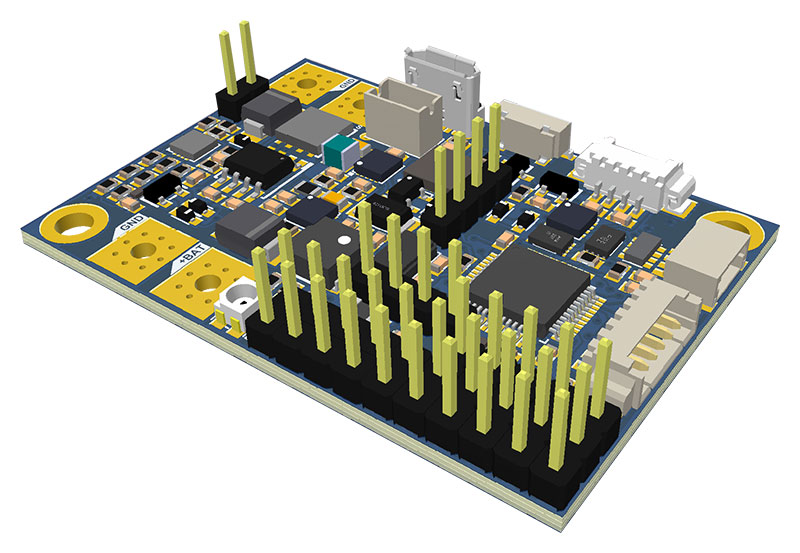

BaseCam SimpleBGC 32-bit CAN_MCU

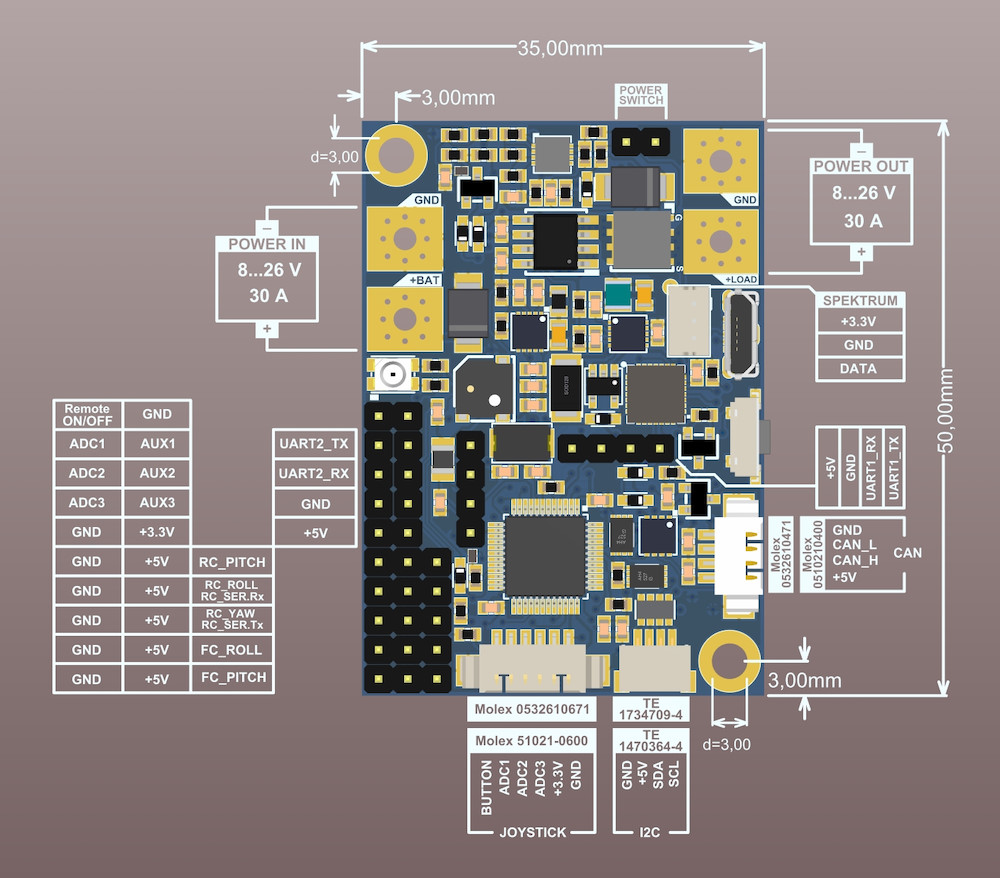

Unlike other BaseCam controllers, SimpleBGC 32-bit «CAN_MCU» controller has no onboard motor drivers and requires external drivers to build a gimbal, as shown in this diagram. It is designed primarily to work with the CAN Driver modules, though «I2C_Drv» drivers are supported, too. It supports both the CAN_IMU and regular I2C IMU sensors.

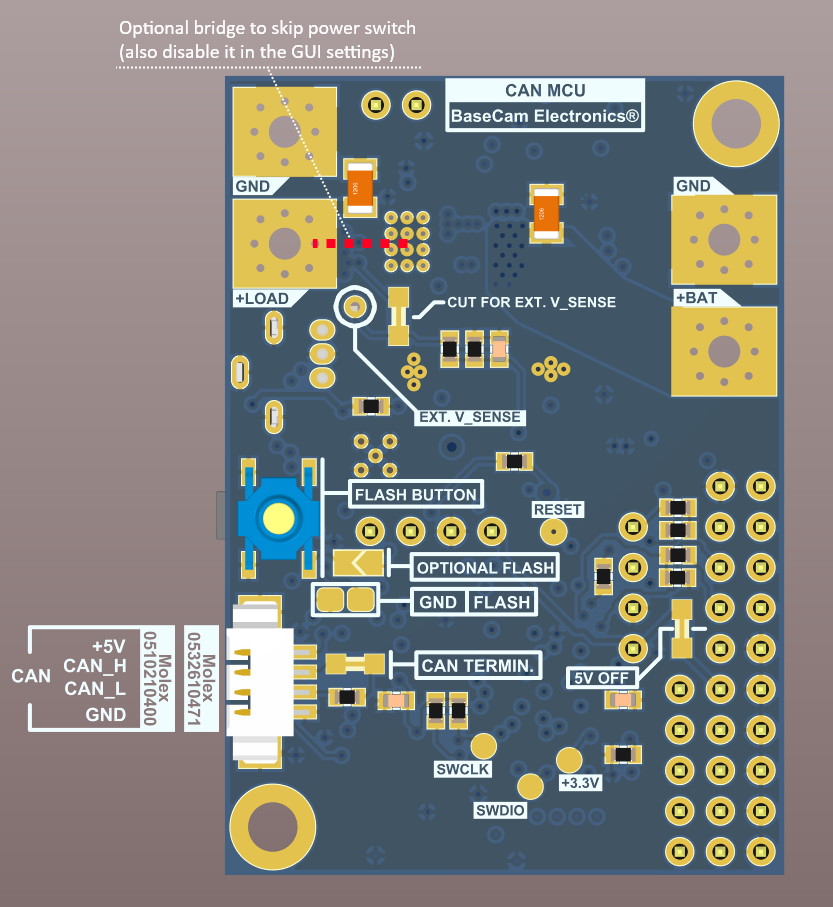

The new important function of this controller is an integrated electronic power switch that could be used as a main power switch for the gimbal*. It allows to communicate currents up to 30A continuous, providing soft startup current to charge buffer capacitors in CAN drivers, can be switched ON/OFF by the external logical input, has overcurrent and Undervoltage protection. It supports two kinds of buttons: latching switch and momentary push button.

This controller is an ideal solution to build

Other features are common for the «Extended» and «Pro» series of controllers:

- Current sensor to measure battery power consumption

2×CAN ports, 1×I2C port- Joystick port having 3×analog signal inputs, mode button input, +3.3V power line

Built-in sound beeper- 3×UARTs for Serial API / Spektrum /

S-bus / External IMU sensors connections - Up to 6s LiPo battery is supported

- Supports extra features in the firmware that are not available in «Regular» and «Tiny» versions (see «Versions comparison chart» in the «Appendix A» of the User Manual)

* This switch should be used only together with the capacitive load — i,e, overall current consumed by all connected devices in first 500ms at startup, should not exceed 1A (roughly). See application note for detailed information.

Capabilities of SimpleBGC32 Gimbal Controller

- Possibility to manage the system on different platforms

- Desktop systems: Windows, macOS, Linux. The firmware of the controller is user-upgradeable (through the GUI).

- Smartphones: Android and some control from 3rd party vendors for Apple's iOS and iPadOS products (iPhone and iPad).

- Open Serial API

- Open programming interface for the development of external control modules — both for software configuration and control of the board and for communication with various electronic devices.

- Automatic tuning of PID parameters

- Allows you to quickly prepare the system for work either at the initial settings or at changed conditions.

- Support of systems with various hardware configurations

- Flexible customization of the sensor orientation.

- Support for a wide range of motors of various configurations and sizes.

- Support several configurations of motor orders, including configurations with the tilted motor axes.

- Support for two IMU sensors and external IMU for maximum precision

- The system works with either one or two IMU sensors. The use of two sensors improves stability and accuracy in the

non-encoder version. - Optional connection of a

high-grade external IMU sensor orMavLink-enabled auto-pilot extends precision for demanding applications. - Support for a wide range of absolute encoders

- Installing an encoder on each motor greately improves system performance and extends the range of applications.

- Different algorithms of follow mode

- Flexible configuration of the following mode for each axis. Automatic switching of horizon axis mode from lock to follow in case of persistent camera tilt.

- Up to five user-configurable modes of system operation selectable with a toggle button

- 5 profiles grouped in 5 profile sets allows changing modes of operation or even hardware configurations

on-the-fly . - Support of a wide range of external control protocols

- Futaba, Spektrum, 5x PWM, Sum-PPM, 3 ADC, Serial API

- Flexible configuration allows for control of any functions of the system (every parameter that the system uses is configurable).

- Battery voltage drop compensation

- This ensures proper control of the drive motors during the whole life of the battery.

- Different versions of the controllers for different needs

- The licensing system allowed our partners to launch different versions of controllers for a wide range of applications: from compact controllers for stabilizers of light cameras to powerful ones for the stabilization of heavy units.

- Ongoing work to improve the system

- BaseCam Electronics is working closely with the developers of end devices, which allows us, on the basis of feedback, to continuously improve the stabilization algorithms and expand the capabilities of the system within a single version of the controller.

Specifications

| Size of the board | 35×50 mm |

| Weight | 9.5 g |

| Diameter of the mounting holes | 3 mm |

| Power supply voltage | 8–26 V (3s-6s LiPo) Powering from +5V is possible ** |

| Power switch continuous current | 30 A* |

| Power switch overcurrent protection |

0 — 40 A adjustable |

| 5V output current |

up to 1 A |

| 3.3V output current | up to 1 A |

* in a short period of time. Can be extended with the proper cooling.

** It's possible to power the board using an external DC/DC +5V if connected to "+BAT" and "+5V out" pins. The "Electronic power switch" option should be disabled in GUI, and "Power switch" is shortened.

Downloads

USB Drivers for PC Connection

If controller being connected to the USB port, is not recognized as COM-port, most probably you need to install or update drivers for CP210x chip. You can download driver for your OS from the manufacturer of CP210x.

AN IMPORTANT NOTE: The latest version (6.7.4) of driver for Windows may cause problems with delay in data transmission, visible as a big lag of the GUI. In this case, install version 6.7.2 of the driver, which had no such problems.

Support

Type your question or comment below. Answer will be sent at your E-mail within 24 hours on workdays.